|

1:Basic parameters |

|

1.1 Outside diameter |

φ114~φ219mm |

|

1.2 Thickness |

3.0~8.0mm |

|

1.3 Sizing length |

4-10m |

|

1.4 Production speed |

0~40m/min |

|

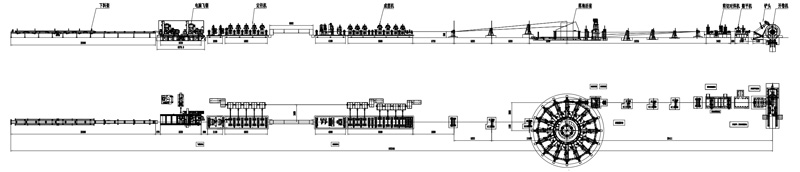

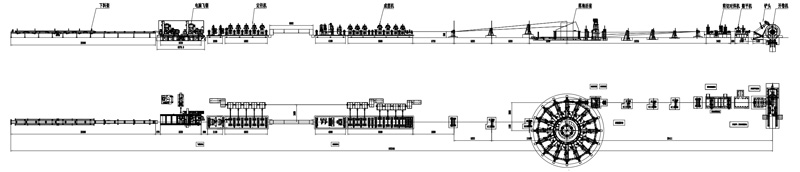

2:Production Process |

|

Coil car→Uncoiler→Shearing and welding machine→Horizontal accumulator→Leveling→Forming machine→HF→scraper→Cooling→Sizing machine→Straighten→Friction/cold saw→Run out table |

|

3:Scope of supply |

|

Equipment component |

Configuration |

|

3.1 Double rolls uncoiler |

Pneumatic |

|

3.2 Shearing and welding machine |

|

|

3.3 Vertical cage |

|

|

3.4 Forming machine |

|

|

3.5 Welding(Mechanical part) |

|

|

3.6 Sizing machine |

|

|

3.7 Saw |

Friction/cold saw |

|

3.8 Run out table |

Single/double side |

|

3.9 600kw solid state HF welder |

Domestic/imported |

|

3.10 Electric control system |

|

|

3.11 Hydraulic/pneumatic system |

|

|

3.12 Roller |

Optional |

|

4:Reference photos (customized equipment, pictures are for reference only) |